Hot Dip Galvanized Cable Tray Manufacturers in Pune, Suppliers and Dealers in Pune, Chakan, Bhosari, PCMC, Talwade, Pirangut, Talegaon and Shirwal

Electrotech Industries is one of the leading Hot Dip Galvanized Cable Tray Manufacturers in Pune, Suppliers, and Dealers in Pune, Chakan, Bhosari, PCMC, Talwade, Pirangut, Talegaon and Shirwal.

As we are a growing company, we are producing aluminum earthing electrodes with advanced features specifically for industrial, and other applications. This updating and developing cable trays that can withstand the harsh weather conditions commonly found in many industries.

We as a hot dip galvanized cable tray manufacturers in Pune, Chakan, offer a wide variety of these cable trays, including a large range of sizes, types, and configurations, catering to diversified customer needs.

About Hot Dip Galvanized Cable Tray:

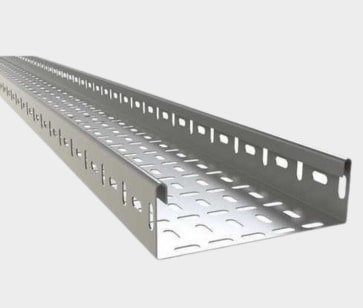

Hot Dip Galvanized Cable Tray is a type of cable tray that is coated using a layer of zinc to protect the cable system from corrosion and rust. The galvanizing process includes dipping the steel cable tray into molten zinc, which makes a strong, robust, durable, and corrosion-resistant coating. We as a hot dip galvanized cable tray suppliers in Pune, Chakan supplies these trays that are suited to any harsh environments where top levels of moisture, chemicals, or other corrosive elements are present. We provide hot-dip galvanized cable trays in different types for varied applications.

Types of Hot Dip Galvanized Cable Trays:

- Ladder Type Cable Tray: It has two longitudinal side rails which joined and structured like a ladder. Ideal for industries with support a wide collection of heavy cables.

- Perforated Type Cable Tray: consists of a solid bottom with small perforations or holes, allowing proper ventilation, and air circulations around cables. They are widely used for commercial installations.

- Trough Cable Tray: symmetrical like a solid bottom cable tray but contains a slightly raised or folded edge. Mostly used in electrical and communication systems.

- Channel Type Cable Tray: Includes a U-shaped cross-section with a one-channel cable tray which is typically used for short spans and light loads.

- Wire Mesh Cable Tray: Highly demanded by data centers and IT corporate offices where high airflow is required for thermal regulation of the cables. These trays are very easy to assemble and remove due to their lightweight nature

- Spine Type GI Cable Tray: It has a central spine or support, with additional rigidity and strength to manage cables in an organized way.

Following are the Types of Hot Dip Galvanized Cable Trays:

Technical Specifications of Hot Dip Galvanized Cable Tray:

As a Hot Dip Galvanized Cable Tray Manufacturers and Suppliers in Pune, Bhosari, PCMC, Talwade, Pirangut, Talegaon and Shirwal. Following are the specifications of Hot Dip Galvanized Cable Tray:

| Specifications | Details |

|---|---|

| Equipment Type | Cable Tray |

| Material Used | GI (Galvanized Iron), Aluminium |

| Length | 10 mtr |

| Thickness | 8 mm |

| Finishing | Polished |

| Usage | Dissipates Lightning Energy |

| Features | Thermal Regulation5tgv |

Benefits of Hot Dip Galvanized Cable Trays:

As a Hot Dip Galvanized Cable Tray Manufacturers, Suppliers and Dealers in Pune, Chakan provide these trays in multiple features for increment of the product appeal. Such features are listed below:

- Superior Corrosion Resistance: The hot dip galvanizing process forms a thick, uniform layer of zinc coating on the trays, allowing superior protection against corrosion. It ensures the durability and longevity of the cable system.

- Longevity: Its robust construction takes a longer lifespan for the cable trays, degrading the requirements for replacements.

- Robust Structural strength: The galvanization process protects the steel while maintaining its structural integrity. These cable trays can support heavy loads without compromising safety or performance.

- Consistency in Quality: Our Hot Dip Galvanized Cable Tray manufacturers in Pune, Chakan able to keep consistency in quality and high standards.

- Reduced heat with Good Ventilation: Its open design ensures large air circulation around the cables that prevent overheating.

- Flexibility and scalable: Easily accessed, added, or removed efficiently. Its expanded structure is suitable for a wide range of cables, including data cables, communication cables, and electrical wiring

- Durable, and portable in Nature: Its robust constructed trays are made using tough material which is capable of carrying heavy loads.

- Required less Maintenance: As these trays are easy to install, they need less maintenance resulting in cost savings.

Applications of Hot Dip Galvanized Cable Tray

As a Hot Dip Galvanized Cable Tray Manufacturers, Suppliers, and Dealers in Pune. Following are the applications of Hot Dip Galvanized Cable Tray.

- Industrial Plants: Our HDG trays are widely used in chemical, Power Plants, Water Treatment Plants, and petrochemical plants, oil/gas industries. Suited to protect electrical and instrumentation cables from corrosive elements.

- Infrastructure Projects: AT many transportation infrastructures, our Hot Dip Galvanized Cable Tray is extensively used in tunnels, stations, bridges, airports, and railways to organize electrical and communication cables. They allow the durability and safety of electrical installations in such settings.

- Commercial Buildings: For High-Rise Buildings including skyscrapers and large commercial complexes, our trays are used to organize and route electrical, data, and telecommunication cables throughout the building.

- Shopping malls and Complexes: Our hot dip galvanized cable tray manufacturers in Pune, Chakan manufacture trays to organize and protect the large volume of wiring that is required for lighting, security systems, and other controls in large commercial complexes.

- Renewable Energy Projects: Suitable for many wind farms and solar plants to manage power and control cables from wind turbines. Its ability to withstand any kind of outdoor environmental conditions.

- Telecommunication and Data Centres: Widely used in communication and Data Centres to fix and protect the vast amount of data and power cables. Their structural strength gives more reliability in data transmission. These trays are also ideal for other communication infrastructures like telecom towers.

- Food and Beverage Industry: In many Processing Plants, our well-structured MS hot dip galvanized cable trays are used to support processing plants.

- Hospitals and Critical Facilities: These cable trays are highly used in hospitals and other healthcare centers to manage the cabling for emergency and backup power systems.

We are Hot Dip Galvanized Cable Trays manufacturers in Pune, suppliers, and dealers in Pune, Chakan, Bhosari, PCMC, Talwade, Pirangut, Talegaon and Shirwal offer the most versatile and robust solutions to organize and protect the cables in a wide range of applications.