Top Cable Tray Manufacturers in India - 2025

Electrotech Industries., leading cable tray manufacturers, suppliers and dealers in India, is offering top-quality cable trays. These cable trays have a rigid structural system and give mechanical support that can hold and protect cables and wires from any kind of external threat.

They are used to organize and route cables for a variety of purposes and these cable trays are made with pure forms of raw materials such as stainless steel and aluminum. Due to its rigid structure, these are highly used in multiple types of applications such as data centers, commercial buildings, solar energy, telecommunications and industrial facilities. These cables are more versatile and able to fit in less space in areas also. Below, we have listed its various types; it’s using benefits and applications also!

Types of Our Cable Tray

Being the former cable tray manufacturers in India, we are offering the best quality of cable tray, and each one is made with pure quality and gives maximum durability. Here, we have listed some types, such as:

- Ladder Cable Tray: These are highly demanding due to their ladder-like structure and are designed with side rails and also have spaced rungs. The ladder cable tray has excellent ventilation support as compared to other trays and is most suitable for heavy-duty cables and high-power electrical installations. Our new modern ladder trays are more lightweight and installed with composite materials, and we have given hot-dip galvanization and powder coatings that can extend tray life. These are often used in server rooms and commercial and residential organizations.

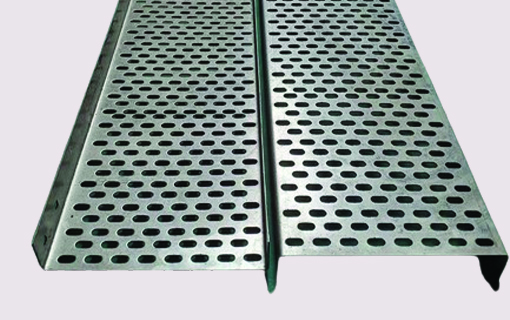

- Perforated Type Cable Tray: These cable trays are widely used in electrical and data cable installation sectors due to their structure. Our perforated cable trays have small holes or slots along with bottom and side rails. It gives partial protection against any kind of damage and allows for good ventilation and drainage. For increasing the performance even in outside environments, we have given powder-coated finishes that can easily resist weather effects, chemicals and heat.

- Solid Bottom Cable Tray: These solid bottom cable trays are the best option for sensitive cables that give continuous support and protection from dust, moisture and external damage. Our new advanced version of the solid bottom cable tray has perforated knockouts that allow for quick and flexible branching of cables without compromising the protection. For more flexibility in using, we have customized these cable trays with removable covers and pre-installed dividers for cable segregation.

- Stainless Steel Cable Tray: Our stainless steel cable trays are in high demand from multiple types of industries due to their top durability. These are highly used in marine, chemical and food processing industries. We have used pure forms of stainless steel alloys, such as duplex and super-austenitic grades, that offer better resistance against corrosion. These trays are all made with pre-polished surfaces that reduce the accumulation of dust and contaminants, which can enhance cleanliness in sterile environments. These are mostly used in industrial facilities, marine areas and hospitals also.

Technical Features of our Cable Trays

For more information about our cable trays, we have mentioned below a technical sheet such as:

| Specification | Ladder Cable Tray | Perforated Cable Tray | Solid Bottom Cable Tray | Stainless Steel Cable Tray |

|---|---|---|---|---|

| Material | Mild Steel, Aluminum | Mild Steel, SS | SS, Aluminum | SS 304, SS 316 |

| Thickness Range (mm) | 1.5 – 3.0 | 1.2 – 2.5 | 1.2 – 3.0 | 1.0 – 2.0 |

| Width Range (mm) | 100 – 1200 | 50 – 1000 | 50 – 800 | 50 – 600 |

| Height Range (mm) | 50 – 200 | 25 – 100 | 25 – 150 | 25 – 100 |

| Length (mm) | 3000 | 2500 – 3000 | 2500 – 3000 | 2000 – 3000 |

| Surface Finish Options | Hot Dip Galvanized, Powder Coated | Pre-Galvanized, Hot Dip Galvanized | Hot Dip Galvanized, Powder Coated | Electro-Polished, Mill Finish |

| Load Capacity (kg/m) | 50 – 300 | 30 – 150 | 40 – 200 | 20 – 120 |

| Bend Radius (mm) | 200 – 300 | 100 – 250 | 100 – 200 | 100 – 250 |

| Operating Temperature (°C) | -20 to +120 | -20 to +90 | -20 to +90 | -50 to +150 |

| Standard Compliance | IEC 61537, NEMA VE-1 | BS EN 61537, ASTM A123 | NEMA VE-1, IEC 61537 | BS EN 61537, ASTM A480 |

| Corrosion Resistance Class (CRC) | CRC 3 – CRC 5 | CRC 3 – CRC 4 | CRC 3 – CRC 5 | CRC 5 |

| Ventilation (%) | 70 – 80 | 30 – 50 | 0 | 0 |

| Weight (kg/m) | 2.0 – 5.5 | 1.5 – 4.0 | 1.8 – 4.5 | 1.2 – 3.0 |

Features of our Cable Tray

One of the former cable tray suppliers in India, these all types of cable trays are made with involving multiple types of features, such as:

- Corrosion Resistance: These are specially designed with pure materials or coatings to prevent rust and corrosion in harsh environments.

- High Load Capacity: These cable trays are made with pure raw materials to support large bundles of heavy cables without bending or sagging.

- Modular Design: These systems allow for flexible installations due to their modular designs.

- Heat Dissipation: Our cable trays have an open structure design, enabling effective heat dissipation. This protects cables from overheating and prevents accidental damage.

- Ease of Maintenance: These cable trays provide easy access to cables for inspection, repairs, or upgrades without dismantling the system.

- Durability: These trays are made from pure raw materials, such as steel or aluminum, ensuring long-term reliability in various conditions.

- Cost Efficiency: These trays can reduce installation time and labor costs compared to traditional cable trays.

Benefits of using our cable tray:

Being the former cable tray dealers in India, all types of cable trays are made with accurate engineering methods and give multiple types of benefits, such as:

- Cost-Effective: Compared to traditional cable trays, our cable trays are a more affordable solution, reducing labor costs and providing cost-effective solutions.

- Easy Installation: These cable trays allow for fast and simple installation, minimizing project timelines and complexities.

- Versatile Design: Our cable trays are versatile and available in various shapes, sizes, and materials to suit diverse industrial and commercial needs.

- Improved Cable Management: Their large capacity provides organized support for any type of cable, facilitating easier routing and management of large cable bundles.

- Scalable Solution: These trays are easily adaptable for future modifications and expansions.

- Enhanced Safety: The outer surface of these cable trays is made from pure materials such as stainless steel and aluminum, protecting against external damage and reducing the risk of electrical hazards.

Applications of our Cable Tray

These all types of cable tray are installed with various types of features and are able to be used in multiple types of applications, such as:

- Electrical power and signal cable distribution systems

- Data communication and networking cable management solutions

- Industrial and manufacturing facility cable routing infrastructure

- Offshore platforms and marine environment cable installations

- Renewable energy plants’ power and control cable support

- Road, rail, and airport infrastructure cabling frameworks

- Heavy-duty and high-voltage industrial cable support systems

- Utility tunnels and underground service cable management

- Residential, commercial, and institutional building cable organization

- Overhead cable routing in public utility networks

Frequently Asked Questions (FAQs)

Cable trays are used to support and organize electrical cables, allowing for safe and efficient routing. They provide a pathway for cables to avoid tangling and damage in commercial and industrial settings.

Cable trays are typically made from materials like steel, aluminum, and fiberglass. These materials ensure durability and corrosion resistance for use in various environments.

The right size is determined by the number and size of cables to be installed, as well as the space available for installation. You should ensure that the tray has enough space to accommodate future cable additions.

Yes, cable trays can be used outdoors if they are made from weather-resistant materials like galvanized steel or fiberglass. It is important to consider the environmental conditions before installation.

As leading cable tray manufacturers, suppliers and dealers in India, we at Electrotech Industries are providing the unique types of cable trays that are used in multiple types of industries due to their working mechanism and structure. These are made with strong quality materials and give more durability as compared to traditional trays and have a large space for maintaining a bulk amount of wires. For more information, contact us today!