Hot Dip Galvanized Cable Tray Manufacturers, Suppliers and Dealers in Mumbai

Electrotech Industries, Hot Dip Galvanized Cable Tray Manufacturers, Dealers, and Suppliers in Aurangabad (Sambhajinagar). Hot Dip Galvanized Cable Trays offer an effective and organized distribution of cables in industrial and commercial buildings. Mild steel (MS) trays are given a coating of zinc by hot dip galvanization during manufacture and thus offer excellent durability while resistant to corrosive action, even under the extreme environmental condition. The two common varieties include MS Hot Dip Galvanized Ladder Cable Trays, which are ideal for heavy-duty applications, and Hot Dip Galvanized Perforated Cable Trays that are made for better ventilation and moderate loads.

Due to sturdy construction and capability to withstand environmental elements, these trays can be relied upon for ensuring the safety and longevity of electrical installations. Adaptive and robust design has made them preferred by many sectors over the years in organized secure cable management.

Electrotech Industries, a pioneer in the electrical solutions sector, stands as one of the most trusted Hot Dip Galvanized Cable Tray manufacturers, suppliers, and dealers in Mumbai. With years of industry experience, we have consistently delivered high-quality cable management solutions designed to meet modern electrical infrastructure requirements. Our products are engineered to withstand extreme conditions while ensuring safety, reliability, and longevity, making them ideal for both industrial and commercial applications.

Types of Hot Dip Galvanized Cable Tray

A well-known Hot Dip Galvanized Cable Manufacturers in Mumbai, we are providing the best quality Hot Dip Galvanized Cable such as:

- Ladder Cable Tray: Ladder cable trays are designed with strong side rails and horizontal rungs, providing excellent support for heavy cables. They are highly suitable for long cable runs and can accommodate frequent changes in direction and elevation. Advanced models now incorporate anti-corrosion coatings and improved load-bearing rungs for enhanced durability in industrial environments.

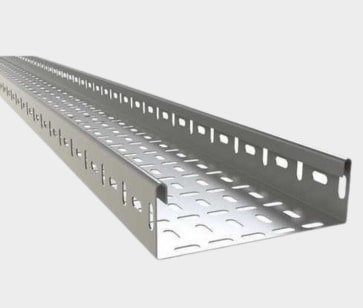

- Perforated Cable Tray: Perforated trays have a solid base with strategically placed holes to allow for air circulation and water drainage. This type is ideal for medium-duty applications where ventilation is essential to prevent overheating of cables. Newer technological formulations in perforated trays include optimized hole patterns to reduce material weight without compromising strength.

- Trough Cable Tray: Trough cable trays feature solid sides and bottoms, offering full protection for sensitive cables against mechanical damage and environmental factors. They are commonly used in areas with high dust, moisture, or chemical exposure. Advanced trough trays now come with improved galvanization techniques that significantly enhance corrosion resistance.

- Channel Cable Tray: Channel cable trays are simple, cost-effective solutions for light to medium cable loads, often used in compact spaces. They provide flexibility for cable routing while maintaining structural integrity and ease of installation. Innovations in channel tray design include modular components and pre-punched mounting options to simplify installation.

- Wire Mesh Cable Tray: Wire mesh trays consist of a grid-like structure, allowing for superior ventilation and flexibility in cable placement. They are highly favored in data centers, IT installations, and areas requiring frequent cable adjustments. Modern wire mesh trays use advanced hot dip galvanization methods to ensure strength, corrosion resistance, and adaptability to heavy cable bundles.

Features of Hot Dip Galvanized Cable Tray

One of the leading Hot Dip Galvanized Cable Suppliers in Mumbai, our all-types of Hot Dip Galvanized Cable are included with new technological formulations such as:

| Feature | Benefits | Technological Advancements |

|---|---|---|

| Corrosion Resistance | Hot dip galvanisation creates a thick zinc coating on trays, preventing rust and chemical damage. This feature ensures a longer lifespan even in harsh outdoor and industrial environments. | Recent advancements in galvanisation now allow coatings to resist extreme weather and industrial pollutants more effectively. |

| High Load Capacity | These trays are engineered to support substantial cable weight without bending or deformation. The design improvements include reinforced rungs and side walls for uniform load distribution. | Technological upgrades have led to increased weight tolerance while maintaining a lightweight structure for easier installation. |

| Durability and Longevity | Hot dip galvanised trays are inherently resistant to wear and mechanical stress. They remain structurally sound for decades, reducing the need for frequent replacements. | Newer formulations also improve impact resistance and reduce micro-cracking under dynamic loads. |

| Easy Installation | Modular tray designs and pre-drilled components allow for quick and hassle-free installation. Trays can be easily joined, extended, or modified on-site, reducing labour time. | Technological innovations now include snap-fit and adjustable supports for enhanced flexibility in complex installations. |

Benefits of Hot Dip Galvanized Cable Tray

- Enhanced Safety: By securely organizing and supporting cables, these trays minimize risks of accidents, short circuits, and electrical hazards. The durable coating prevents cable exposure to corrosive elements. Modern designs incorporate fire-retardant properties to comply with updated safety standards.

- Cost-Effectiveness: While initial costs may be higher, the long lifespan and reduced maintenance make them economical in the long run. Fewer replacements and repairs translate into substantial savings over decades. New manufacturing methods also allow bulk production without compromising quality, reducing procurement costs.

- Scalability: Cable trays provide a structured pathway for expanding electrical systems without major infrastructure changes. Additional trays and supports can be seamlessly integrated. Technological improvements include modular designs and adjustable fittings for future-ready scalability.

- Improved Cable Management: They maintain organized cable routes, reducing clutter and potential signal interference. This is particularly critical in data centers and industrial facilities. Innovations now include color-coded trays and cable labeling systems to simplify identification and maintenance.

Applications of Hot Dip Galvanized Cable Tray

- Industrial Plants: Cable trays are essential for supporting extensive electrical wiring in factories and manufacturing units. They facilitate easy access for inspections, maintenance, and upgrades. Recent applications include integration with smart sensors for monitoring cable load and temperature in real-time.

- Commercial Buildings: Offices, malls, and high-rise complexes rely on trays to manage complex electrical networks efficiently. They ensure safety and streamline electrical maintenance. Technological updates include aesthetically designed trays that blend seamlessly with modern architectural interiors.

- Data Centers: Wire mesh and perforated trays provide optimal airflow for heat-sensitive IT cables. They prevent overheating and improve the longevity of networking equipment. Advanced models now incorporate modular cooling channels and cable routing for high-density server environments.

- Telecommunication Networks: Structured cable pathways are critical for telecom towers and urban infrastructure. Trays protect cables from environmental exposure and mechanical stress. New designs support high-speed fiber optic installations with improved grounding and shielding techniques.

Electrotech Industries is a leading Hot Dip Galvanized Cable Tray manufacturers, suppliers, and Dealers in Mumbai. Our wide range of cable trays incorporates the latest technological advancements in corrosion resistance, load-bearing capacity, and installation flexibility. By choosing Electrotech Industries, clients benefit from reliable, durable, and efficient cable management systems that cater to diverse industrial, commercial, and infrastructure applications while ensuring future-ready scalability and sustainability. Contact us today for more information!